by Antonino Genovese – Head of Laboratory of Systems and Technologies for Sustainable Mobility, ENEA; Fernando Ortenzi, Francesco Vellucci - Laboratory of Systems and Technologies for Sustainable Mobility - ENEA

Transportation sector, which represents the source of one third of total CO2 emissions in the EU, could benefit from the renewed attention on green hydrogen, since, as energy vector it could help to replace fossil fuels and reach EU climate change targets. Hydrogen could be a lead actor for transport decarbonisation especially in those sectors, such as aeronautics, long-haul road, maritime transport, and railways, where batteries are an impracticable solution to substitute fossil fuels, due either to the large amount of energy required or the long distance that needs to be covered. At the same time, a great interest has been shown to replace ICE Diesel technology in heavy-duty transport with hydrogen technology. Hydrogen will be able to contribute to the efforts for transport decarbonisation, working together with electrification and not in competition with it, filling that gap that could not be technically or cost-effectively covered by batteries.

Il settore dei trasporti, causa di un terzo delle emissioni di CO2 in Europa, potrebbe trarre giovamento nell’impiego di idrogeno verde quale sostituto dei combustibili fossili per conseguire gli obiettivi di neutralità climatica individuati dalla UE. L’idrogeno ha potenzialità per assumere un importante ruolo in quelle aree ove le batterie mostrano limiti applicativi per via delle maggiori distanze da percorrere o per il maggior contenuto di energia da porre a bordo dei veicoli, come nel trasporto marittimo, ferroviario, stradale di lunga percorrenza, aeronautico. Allo stesso tempo, è stato mostrato un grande interesse nel sostituire la tecnologia dei motori a combustione interna Diesel con la tecnologia dell’idrogeno nel trasporto pesante. L’idrogeno avrà modo di contribuire agli sforzi di decarbonizzazione del trasporto, lavorando in cooperazione e non in competizione con l’elettrificazione, colmando l’ambito applicativo ove le batterie non trovano convenienza tecnica-economica.

Nowadays we are witnessing a revival of interest for hydrogen as energy carrier in several application fields. Paraphrasing the homonymous movie of the mid ‘80s we can say that hydrogen “comes back to the future”. The renewed focus presents hydrogen as a key pillar to decarbonise energy sectors characterized by high carbon footprint that might find hard or expensive to deploy other solutions. However, this statement will be successfully verified only if hydrogen will be produced from renewable energy, giving rise to the so-called “green hydrogen”, or from other colored pathways which will be able to offer a safe, cost-effective and CO2 emissions free hydrogen source.

Transportation sector represents the source of one third of total CO2 emissions [1] in Europe (EU) and it could benefit from the renewed attention on hydrogen to replace fossil fuels and meet the EU decarbonisation targets. The ongoing revolution in road transport is oriented to substitute petrol and Diesel-powered vehicles with less CO2 emitting vehicles preferring electrification as the main solution. Cars and motorcycles powered by batteries have good chance to reduce CO2 and pollutants emission having zero “on road” emissions while overall emissions depend on the energy mix used to generate electric energy. Battery electric vehicles (BEVs) range and recharging time are now more responsive to user needs and make BEVs more attractive to meet mobility requirements on short-medium range daily trips. Current batteries for cars have energy capacity up to 100 kWh, offering real range of 300 km and over. Heavy duty vehicles engaged in long range transport and public transport buses, usually powered with Diesel internal combustion engine (ICE), are less suitable to be substituted by battery powered vehicles because they would need a larger battery capacity in order to run appropriate distances. Battery packs would be result bulky and heavy and, moreover, charging power should be rather high to limit the charging time.

Hydrogen in transport could be a lead actor in sectors where batteries are an impracticable solution to substitute fossil fuels as well as for maritime transport (ferries, coasting trade or inland waterway) and in rail application. At the same time, a great interest has been shown to replace ICE Diesel technology for heavy duty transport with hydrogen technology. First prototypes of H2 trucks have recently been unveiled by Toyota, Nikola and Hyunday while other manufacturers have just started to undertake this promising challenge.

H2 as fuel in internal combustion engines

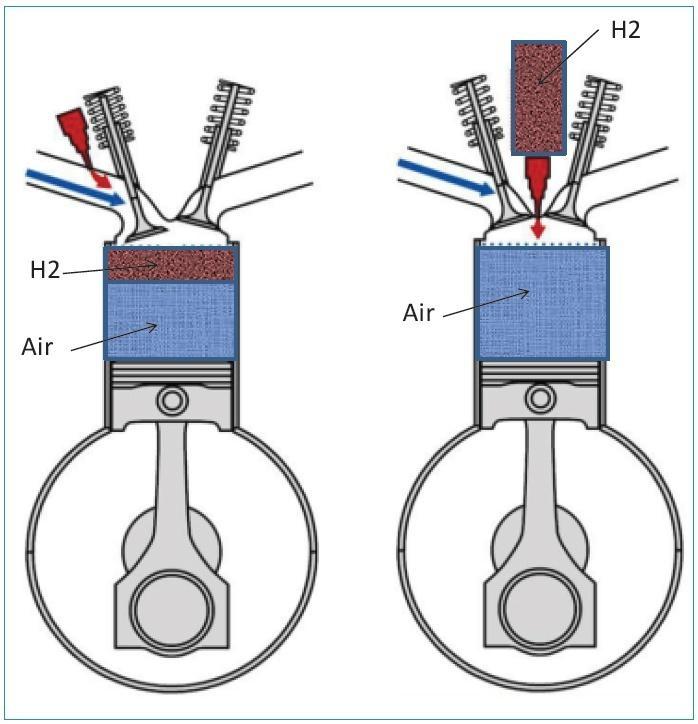

Hydrogen is an energy carrier capable to power road vehicles in two ways: as fuel to be injected in the ICE or as fuel to supply the Fuel Cell (FC) system. ICEs can be modified or redesigned to run on 100% H2, exploiting hydrogen properties as fuel: wide range of flammability, high flame speed, low ignition energy, high diffusivity. ICE is a mature technology and could be converted to run on hydrogen, given the benefits from already existing manufacturing facilities. H2 ICEs can result cheaper, less dependent on rare and expensive materials and more tolerant to hydrogen impurities compared with FC technology. Although the H2 ICE emission is water vapor, traces of carbon-based emissions (CO, HC) could be present in the exhaust gas due to oil lubricants and NOx resulting from oxidation of nitrogen (N2) in the air by high combustion temperature. Feeding H2 to ICEs in a lean condition with exhaust gas recirculation (EGR) minimizes the NOx emissions. Alternatively, a stoichiometric combustion can be combined with a three-way catalytic converter in order to reduce NOx. Fuel injection in the intake manifold is the solution employed in many demonstration prototypes but this technology is affected from a reduced power density since a large volume of H2 leads to a displacement of air in cylinders (Figure 1). This drawback can be solved using direct injection, a solution able to increase the volumetric efficiency with an injection pressure higher than 100 bar which overcomes the high in-cylinder pressure. In 2009, BMW equipped an H2 ICE with a high pressure direct injection system (300 bar) and reached a 42% of maximum efficiency similar to a Diesel engine [2]. In Hyfleet:CUTE (2006-09) and CHIC projects (2010-16) H2 ICE buses based on naturally aspirated injection were put in regular service showing a service availability larger than 89% [3]. In H2 ICEs attention must be drawn to the embrittlement coming from hydrogen diffusion inside crystalline lattice of materials that could lead weakening and cracking phenomena.

A soft application of H2 in ICE is possible fueling engine with a blend of natural gas/hydrogen (NG/H2). In this case H2 operates as “additive” to natural gas giving advantages which make it possible to operate lean combustion thanks to the improved performance in combustion kinetics and flame propagation. The use of hydrogen blends is supported by other aspects such as the possibility to use the exiting NG pipeline for mixture supply to refueling stations. The NG/H2 blend leads to a CO2 reduction due to the hydrocarbon molecules substitution with hydrogen molecules and a possible additional reduction for a major efficiency resulting from the higher combustion speed. Obviously NG/H2 blends are not a carbon-free fuel but can be a solution to support the transition toward a 100% carbon-free transport.

FC for road transport

A Fuel Cell is an electrochemical device where hydrogen and oxygen react, converting chemical energy to electric energy and giving water as reaction product. Reactants are introduced individually in two electrodes separated by an electrolyte which avoids direct mixing of the reactants but allow the transfer of ions. The most common technologies adopted in transport are based on the use of a Polymeric Electrolyte Membrane (PEM) as electrolyte. This kind of electrolyte makes this FC technology interesting thanks to the low operating temperature (70-90 °C), compactness and power density. Usually, a platinum catalyst is used to facilitate reduction and oxidation reactions. The performance of PEM FCs depend on the different components but also on operating parameters such as humidity and temperature. The high efficiency that characterizes PEM FCs makes them competitive in energy term while durability is another important requirement in order to meet transport needs yet. In transport applications reference lifespan (defined as the maximum lifetime of a FC with no more than 10% loss in efficiency) are 6,000 hours for cars and 20,000 hours for buses respectively. Higher FC lifespan are required for a long haul application where a high mileage is expected: 50,000 hours and over is the target. At present, FC vehicles are expensive, although mass-production could reduce costs, bringing them closer to other powertrains. Platinum catalyst is a rare material having a yearly production of 170 tons in 2020 with two third of world production in South Africa. This resource could be subject to market variability, a potential risk factor for future supply. To avoid this uncertainty, manufacturers are engaged to decrease platinum content in order to reduce FC cost and to push the volume scale up. Another critical point to large mass market diffusion is hydrogen storage: pressure vessel up to 350 or 700 bar is the option adopted for passengers cars, but other solutions as liquid cryogenic hydrogen are under investigation in order to increase the storage energy density. FC vehicles present a longer driving range in comparison with BEV and a refueling time comparable with ICE vehicles. Market of FC cars presents a small number of models (i.e. Hyunday Nexo, Honda Clarity ,Toyota Mirai) powered by FC and currently available for sale.

H2 in rail transport

Hydrogen mobility is proving to be a valid alternative to Diesel fueled trains on non-electrified lines in Europe. Hydrogen trains are considered competitive for those railway sections not electrified, with low frequency of service and operating on long distances. These conditions are frequent in rail transport, making hydrogen rail mobility interesting from an economic point of view and an excellent opportunity to further decarbonise public transport. The fuel cell technology, unlike other "clean" technologies such as batteries, is able to offer high range in terms of mileage and high nominal driving power. The "Coradia iLint" train (Figure 2) by Alstom [4], for example, has H2 tanks which ensure an autonomy varying from 600 to 800 km depending on the conditions of the route and the service offered; it is also capable of reaching a maximum speed of 140 km/h having a total available power of 850 kW and passenger capacity of 327 seats.

The National Hydrogen Mobility Development Plan for Italy [5] released by H2IT consortium underlines that in Italy there are favorable conditions for consistent introduction of H2 trains. The refuelling of H2 trains is programmable, so the refuelling station can be also used for other users such as buses or private cars. The H2iseO project [6] developed by the railway company FNM, involves the purchase of 6 hydrogen trains produced by Alstom, with the option for the supply of additional 8 trains, which from 2023 will serve the non-electrified Brescia-Iseo-Edolo line in replacement of the current 14 Diesel trains; this project envisages the construction of hydrogen production plants, initially intended for new clean energy trains and, by 2025, also for local public transport and freight logistics.

H2 in maritime sector

The maritime sector is a major consumer of oil products, accounting for about 5% of the World’s demand [5]. As it uses heavy oils as fuel, it has detrimental effects on air quality, particularly around ports. In 2018, the International Maritime Organization introduced and adopted a real strategy in order to reduce total annual greenhouse gas emissions from international shipping by at least 50% by 2050 compared to 2008 [7]. In this context, hydrogen takes advantage of the opportunity to reduce not only emissions during sea navigation, but also those deriving from port operations. In this perspective, the use of energy carriers and alternative fuels with a reduced environmental impact is the key to reach the objectives of reducing greenhouse gas emissions. The current role of the maritime sector in H2 deployment is limited to demonstration projects involving ships for river waterway, coastal crafts and ferries powered by hydrogen produced from renewable sources. The first experience of a hydrogen-powered boat in Italy was made in 2009, in Venice, with the construction of the “Accadue” water bus, a prototype powered by fuel cells [8]. Later, an evolution of the aforementioned prototype, the ferry called HEPIC (Figure 3) was also built in the Venice lagoon [9]. As far as large ships are concerned (on board installed power capacity of a few tens of MW) it seems currently difficult that propulsion would be driven by hydrogen fuel cells, especially considering the large volumes that would be necessary for storage. It therefore appears more likely that, for systems that require high power, hydrogen could be used more for power supply of some auxiliary services rather than for propulsion. Therefore, hydrogen offers an interesting potential for passenger ferries operating on short distances (for example those for city use) generally having a limited power and autonomy request so that the space necessary for the storage of hydrogen on board would not be excessive, silence and the reduction of emissions are factors of great importance. Hydrogen-based technologies for maritime transport have big potentials in Italy, considering the number of ports and their volumes. Making industrial ports strategic hubs for hydrogen use for different types of activities would strongly boost the hydrogen market in activities closely related to it including, for example, goods mobility such as material handling and heavy transport. Ports are an ideal logistic ecosystem for creating synergies that can lead to a reduction in operating costs and several projects are active on this matter.

Projects and perspectives

Differently from a few years ago, the exploitation of hydrogen as energy carrier is now supported by increasing availability of renewable energy that makes hydrogen a “green fuel”. Storing energy as hydrogen is a valid option to balance the power grid, making large volumes of green hydrogen available when produced in electrolyzer plant. To make hydrogen attractive the production cost would decrease in a way that supports the hydrogen economy in the transport sector. Research and technologic progress in FC in the next years should offer higher lifespan, lower sensitivity to hydrogen impurity, deployment of cheaper catalyst materials in order to make hydrogen a real democratic fuel for environment preservation.

The current revival of interest for hydrogen as energy carrier has the potential to provide a significant positive impact on the decarbonization of the transport sector, especially where the limitations of electric solutions (batteries) represent relevant economic and/or the technical burdens, as it is the case of long range heavy vehicles. Therefore, hydrogen will be able to contribute to transport decarbonisation working together with electrification and not in competition with it, filling that gap that could not be technically or cost-effectively covered by batteries.

REFERENCES

- https://www.iea.org/data-and-statistics

- https://www.press.bmwgroup.com/usa/article/detail/T0020216EN_US/bmw-hydrogen-engine-reaches-top-level-efficiency?language=en_U

- https://www.eltis.org/sites/default/files/case-studies/documents/hfc_brochure_10_12_09_4.pdf

- https://www.alstom.com/solutions/rolling-stock/coradia-ilint-worlds-1st-hydrogen-powered-train

- https://www.h2it.it/wp-content/uploads/2019/12/Piano-Nazionale_Mobilita- idrogeno_integrale_2019_FINALE.pdf

- https://www.trenord.it/news/trenord-informa/comunicati-stampa/fnm-e-trenord-lanciano-la-prima-hydrogen-valley-italiana/

- http://www.imo.org/en/MediaCentre/PressBriefings/Pages/06GHGinitialstrategy.aspx

- https://corrieredelveneto.corriere.it/veneziamestre/notizie/cronaca/2009/6-aprile-2009/prima-barca-laboratorio-idrogeno-varata-porto-marghera-1501157557929.shtml

- https://www.alilaguna.it/progetto-hepic