Proposal for a Scaling Tool Under the REACH Regulation

The Scaling tool development (only for liquid chemicals) was based on the Stoffenmanager model for risk and exposure assessment. First, the Stoffenmanager model was analyzed in order to reproduce the rationale it stems from; then the Scaling tool was developed by using the identified rationale. The developed tool allows downstream users, receiving the general Exposure Scenario provided by the producer/supplier, to adapt the scenarios to their operational conditions and risk management measures and check if a given chemical is used safely; in other words if the Risk Characterization Ratio is below 1

Proposta di uno strumento di Scaling nell’ambito del Regolamento REACH

Nell’ambito del Regolamento REACH è previsto l’uso dello Scaling all’interno dello Scenario di Esposizione. Nel REACH non viene definito in modo univoco come effettuare l’operazione di Scaling; questo può comportare specialmente per le PMI difficoltà e costi aggiuntivi. Per questo viene qui proposto uno strumento che semplifica il calcolo dello Scaling. Questo strumento (valido solo per sostanze chimiche liquide) viene costruito prendendo come riferimento il modello di valutazione di esposizione e di rischio Stoffenmanager. È’ stato prima analizzato il modello Stoffenmanager al fine di riprodurre la logica operante, poi è stato realizzato lo strumento Scaling che permette, in modo semplificato, agli utilizzatori a valle che ricevono uno scenario di esposizione, di controllare se, anche avendo condizioni operative e misure di gestione del rischio differente dal fornitore, il loro uso è un uso sicuro, ossia se il Rapporto di Caratterizzazione del Rischio (RCR) conduce ad un valore inferiore ad 1

Roberto Carletti, Stefano Castelli, Flaviano D’Amico, Tanya Boyadzhieva

The Regulation (EC) n. 1907/2006 of the European Parliament concerning the Evaluation, Authorization and Restriction of chemicals (REACH) [1] aims mainly at improving the knowledge about the risks arising from existing and new chemicals and, at the same time, maintaining and enhancing the competitiveness and innovative capacity of the European chemical industry.

The development of the Exposure Scenario (ES) [2] –that is a tool for assessing the risk in the use of chemicals with respect to the categories of workers, consumers and the environment– plays an important role for some types of substances under the REACH Regulation. The ES is the basis for a quantitative estimate of exposure and the means by which an important part of communication in the supply chain between manufacturers / importers and downstream users is achieved. The ES must include the main parameters that determine the release of the substance and exposure, the so-called determinants.

Generally the determinants are divided into two categories: operational conditions (OC) and risk management measures (RMM). The OC refer to instruments or parameters which act during the production or use of a substance that may impact on the exposure of humans or the environment; the RMM include any action or instrument introduced during manufacture or use of a substance to prevent and/or control/reduce exposure of humans or the environment.

The scaling comes into play when the ES developed by the manufacturer or importer passes, through the provision of Safety Data Sheets (SDS), to the downstream user in the supply chain; he must determine that the OC and its RMM are in accordance with the specifications given in the ES. If there are any differences in the OC and RMM, then the user is required to verify whether also in its different conditions the use of the substance is safe, i.e. if the Risk Characterization Ratio (RCR) value is below 1. This operation is called Scaling. Our proposal about Scaling has the aim to define and create for the first time under REACH, an operational tool that allows SMEs to perform the Scaling easily and quickly with no need for external expertise nor staff transfer to make model calculations or use other in-house made methods. So, this tool may provide advantages both in terms of costs and time.

Defining the Scaling

Scaling refers to any operative process, carried out through function, algorithms, tables, spreadsheets or programs, that allows to recalculate the risk depending on the OC and RMM associated with the use of the substance.

The Scaling[3] can be used only for the parameters specified by the supplier, and only according to the measurement tools or models that have been used for the RCR calculation in the ES. The use of the scaling is not allowed if the adjustment of a crucial factor produces different exposure routes, or exposure affects different target groups or if the duration and/or frequency of exposure changes significantly, resulting in a different kind of exposure (for example, acute exposure rather than chronic exposure).

The application of mathematical formulas for scaling calculating is considered to require a good knowledge about issues associated with exposure; also tables or spreadsheets may be tools not so easy to use or of limited value; a table or set of tables containing all OC and RMM modes would be difficult to understand and use. Instead, the use of a spreadsheet would imply some difficulties due to the necessary computing experience required to navigate in a very structured tool.

Using the same model for the RCR calculation is another alternative to compute scaling, but this choice presupposes that the use of the model itself is known, which is not always possible, particularly within SMEs, due to the lack of staff skilled in these issues.

Although major research centers (ECETOC) dedicated to chemicals have attempted to define how to apply the scaling: “The concept of scaling is very recent and not yet well defined” [4] and the attempts to formalize and define the use of the scaling still do not specify how a tool Scaling should be built[5].

Reference Model: Stoffenmanger

Stoffenmanager[6] is a tool for the estimation of inhalation exposure to chemicals (www.stoffenmanager.nl). It is based on 14 parameters (some dependent on one another, other independent) that may vary along a categorized scale; the only parameter that varies continuously is the concentration of the substance [7] [8] .

Each combination of these parameters identifies a precise use of the substance. Through a series of software-driven steps, each identifying a group of variables, the modes of each parameter are selected and entered in the software. The result is expressed as a quantitative estimate in micrograms / cubic meters about the worker’s exposure. The exposure value divided by the calculated DNELs gives the final RCR value.

The model has been validated[9] and is now one of the recommended models [10] under REACH by ECHA (European Chemicals Agency) as well as one of the models that offers a wide range of determinants that can be used in the calculation of exposure and RCR.

Defining of Scaling tool

The Scaling tool was designed like a data input mask reproducing the same choice of parameters of the models. The important new feature is that the Scaling tool will show a field where the RCR value read in the SE attached to the supplier’s SDS can be entered.

User can thus modify the fields of OC and RMM that differ with respect to the ES and immediately compute the new risk value about the chemical.

The list of variables and their properties is as follows.

TABLE 1

Variables used in the Stoffenmanager program

|

No |

Description |

Kind of the variable (*) |

Relationship |

Symbol |

|

1 |

Substance concentration (%) |

continuos |

independent |

C. |

|

2 |

Task characterizing: (handling) |

categorized (8) |

independent |

H |

|

3 |

Duration task: (h/day) |

categorized (4) |

independent |

T |

|

4 |

Frequency task: (day/week) |

categorized (6) |

independent |

F |

|

5 |

Daily cleaning |

dichotomous (2) |

dependent |

P |

|

6 |

More than one employee simultaneously |

dichotomous (2) |

dependent |

L |

|

7 |

Period of evaporation, |

dichotomous (2 |

dependent |

E |

|

8 |

Maintenance |

dichotomous (2 |

dependent |

M |

|

9 |

Distance from task > 1 m. |

dichotomous (2) |

dependent |

D |

|

10 |

Room Volume (m3) |

categorized (4) |

dependent |

Vo |

|

11 |

Specific ventilation |

categorized (3) |

dependent |

Ve |

|

12 |

General ventilation |

categorized (5) |

independent |

V |

|

13 |

P.P.E. |

categorized (8) |

independent |

PPE |

|

14 |

Worker protection |

categorized (3) |

independent |

Pr. |

(*) The numbers inside parentheses indicate the number of categories into which the variable is divided

The Stoffenmanager program requires entering data into 14 variables (determinants).

The variables are distinguished according to their characteristics:

- Nature of variables: continuous or discrete (between this latter dichotomous or categorized).

- Relational system: independent or dependent variables.

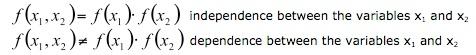

The dependence in the variables implies that the effect of a variable in the output of the program cannot be checked only by varying the variable itself in its modalities (categories representing its range of values), but rather the conjunction with the variable(s) which show(s) dependence to it must be verified.

In practice it is necessary to verify all combinations of the mode of variables and control the effect they have on the output of the program.

The independent variables can be verified “separately”, by varying only the chosen variable and controlling the relationship (linear or not) with the output.

The table above shows that 6 variables are independent, so that each can be checked individually. The remaining 8 are dependent, and must be verified according to an experimental design.

The mechanism of the Scaling tool consists in calculating the specific user’s RCR by changing the OC and RMM variables provided by the supplier in the ES and introducing the user’s specific OC and RMM. The OCs and RMMs are contained within the 14 variables presented in the table above.

For any relationship between the respective pairs of variables (user / provider), based on selected categories in the variables, a value equal to 1 will be assigned if the conditions between user and supplier are the same or will be different from 1 in the remaining cases. This numerical value is called “weight”.

Therefore, the weight is calculated as the ratio between the supplier’s exposure and the user, calculated before and after the change of the variables. The exposure will be calculated by using the Stoffenmanager model.

Example: keeping all other variables constant, the variable type of ventilation (Ve) -3 categories- is varied between the two scenarios:

Ve(1) = no ventilation

Ve(2 ) = L.E.V

Ve(3 ) = L.E.V + containment of the sources

The supplier has implemented the condition Ve(3) and the user the condition Ve(2), the respective exposure values and the ratio have been calculated, thus the weight determining the changing of exposure and RCR from one mode of a variable to another is obtained:

![]()

In the case of independent variables the calculation of weights is quite easy: the exposure is computed by varying the categories of the variable taken into account, while the other variables remain constant.

In the case of dependent variables, the calculation is more demanding: there is the need to find all possible combinations between 8 variables (2268 combinations) and calculate the exposure variation for each of them, hence finding the relative weights; the result is a vector containing the 2268 weights which all together explain the function made explicit below.

![]()

Distribution function of dependent variables

Integrating the distribution function of the dependent variables with each ratio explains the relationships between independent variables, thus we obtain the overall formula of the scaling.

![]()

Scaling Function

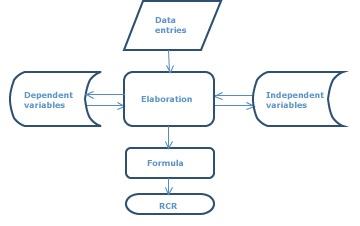

The Scaling tool is therefore composed of a mask data input procedure; lines of instructions (in Visual Net or Excel) that manage the inputs and the dependent or independent variables, and finally a matrix containing all the different combinations of variables (and of the modes), with the relative weights.

The final value is a recalculated RCR which takes into account the different OC and RMM applied by both supplier and user.

FIGURE 1

Logical scheme of the Scaling tool

Validation

The Scaling tool has been validated through a systematic procedure.

All possible combinations of the Stoffenmanager model parameters, distinguishing between dependent and independent parameters have been calculated.

Then, a sample of about 20,000 cases has been selected in such a way to ensure the representativeness of the selected sample with respect to the reference population.

In order to ensure the maximum validity of the operations, the most extreme modes of the parameters have been included in the test sample.

Both the Stoffenmanager model and the developed Scaling tool have been run for each of the about 20,000 combinations.

Finally the results were verified by comparing the RCR value (risk characterization ratio) obtained by using the two procedures; in all comparisons the developed Scaling tool has reproduced the same result obtained with the Stoffenmanager model.

Practical examples of Scaling application and interpretation

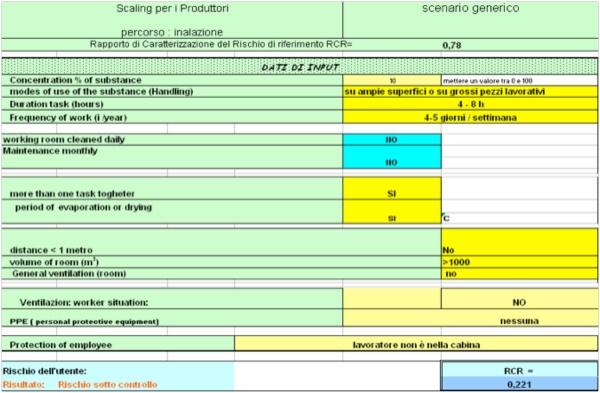

It is assumed that a manufacturer delivers an ES attached to SDS where, with a set of RMM and OC and, the risk is under control: RCR = 0.780.

The Downstream User (DU) verifies that one of OCs is different: the manufacturer reports "use of the substance at low pressure, low speed and mid-surface", while the user applies "use on large areas or large pieces of business." By applying the Scaling tool it is verified that RCR = 1.396, quite beyond the permitted threshold. Through the use of the instrument it can verify several Scaling options, which cut the risk under the allowed threshold and choose the most convenient in terms of cost and time of application.

1° Option: ventilation in the work place Ý RCR = 0,738

2° Option: move the process in a larger worker place (from a place with a volume <100 m3 to another with volume> 1000 m3) " RCR = 0.221.

These and other options are easily verifiable by acting on the scaling tool and can provide the user with a range of options that can be chosen on the basis of both economic and realization-time considerations.

As an example, in the table below the manufacturer OCs reported in the ES, the DU’s initial conditions and the condition variations of the two DU options are shown in order to comply with RCR threshold (last line of table). In Fig. 2, an example screen view of the scaling tool final result is reported.

TABLE 2

Example of the Scaling tool application: Comparison between the CO/RMM in the ES of the manufacturer, CO/RMM initial of DU and two of the possible options for reducing RCR

|

n° |

ES Parameters |

Manufacturers |

DU initial |

DU I° option |

DU II° option |

|

1 |

Substance concentration (%) |

10 |

10 |

10 |

10 |

|

2 |

Handling |

Low pressure and speed, medium surfaces |

Large surfaces or large workpieces |

Large surfaces or large workpieces |

Large surfaces or large workpieces |

|

3 |

Duration task: (h/day) |

4-8 |

4-8 |

4-8 |

4-8 |

|

4 |

Frequency task: (day /week) |

4/5 |

4/5 |

4/5 |

4/5 |

|

5 |

Daily cleaning |

No |

No |

No |

No |

|

6 |

More than one employee simultaneously |

Yes |

Yes |

Yes |

Yes |

|

7 |

Period of evaporation |

Yes |

Yes |

Yes |

Yes |

|

8 |

Maintenance |

No |

No |

No |

No |

|

9 |

Distance from task > 1 m. |

No |

No |

No |

No |

|

10 |

Room volume (m3) |

<100 |

<100 |

<100 |

>1.000 |

|

11 |

Specific ventilation |

No |

No |

No |

No |

|

12 |

General ventilation |

No |

No |

Natural/ Mechanical |

No |

|

13 |

P.P.E. |

No protection |

No protection |

No protection |

No protection |

|

14 |

Worker protection |

Out of cabin |

Out of cabin |

Out of cabin |

Out of cabin |

|

RCR |

0.780 |

1.396 |

0.736 |

0.221 |

|

Note: the yellow field identifies the OC/RMM that differ between manufacturer and DU; the bold identifies the change implemented in order to achieve a safe use.

FIGURE 2

Example screen view of the scaling tool (option II°)

Final conclusion

Compared to other types of Scaling tool, this developed and validated tool is much easier to use, thanks to its simplified format of fields/masks and to its higher ductility, also given by the use of the flexible Stoffenmanager reference model. These features will convert into a significant aid especially to SMEs in complying with REACH obligations.

Reference

- “Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) Regolamento” 1907/2006 (CE), (2006), ECHA, Helsinki.

- “Guidance on information requirement and chemical safety assessment R.14: occupational Exposure Estimation”, (2008), ECHA, Helsinki.

- Guidance on information requirements and chemical safety assessment. Part G: extending the SDS, (2008), Maggio, ECHA, Helsinki.

- ECETOC TRA version 3: Background and Rationale for the Improvements, (2012), Technical Report No. 114, ECETOC AISBL, Brussel.

- J. Tolls, (2011), “Improving ES communication: (IT) Tools and Scaling”, (DUCC/Henkel) 12/13/2011 REACH Implementation Workshop X.

- H. Marquat, et all, (2007), “Stoffenmanager, a web-based control banding tool using an exposure process model”, TNO/Arbo Unie –report.

- E. Tielemans, et all (2008), “Stoffenmanager Exposure Model: Development of a Quantitative Algorithm”, Ann. Occup. Hyg., pp. 1-12,Oxford University Press, Oxford.

- E. Tielemans, et all (2008), “Stoffenmanager , a Web-Based Control Banding Tool Using an Exposure Process Model”, Ann. Occup. Hyg., Vol. 52, No. 6, pp. 429-449,Oxford University Press, Oxford.

- J. Schinkel, et all. (2010), “Cross-validation and refinement of the Stoffenmanager as a first tier exposure assessment tool for REACH”, Occupational Environmental Medicine. 2010 Feb;67(2):125-32, BMJ, London.

- “Guidance on information requirements and chemical safety assessment Chapter R.14: Occupational exposure estimation”, May 2010, ECHA, Helsinki.