Hydrogen and fuel cell activities at the U.S. Department of Energy

by Sunita Satyapal

DOI 10.12910/EAI2021-006

At the U.S. Department of Energy (DOE), hydrogen and related technologies have been part of a comprehensive portfolio of activities for many years. Today fuel cells and hydrogen systems are becoming more available for multiple applications, but the primary barriers to widescale availability across sectors are still: cost, infrastructure and limited scale. To address these challenges, DOE’s Hydrogen and Fuel Cell Technologies Office (HFTO) has a comprehensive portfolio of activities in R&D as well as enabling demonstration and deployment. DOE also has stewardship of 17 national laboratories across the U.S. with world-class, unique capabilities and over 50 Nobel Prize winners and experts tackling some of the most pressing energy challenges of our time.

Il Dipartimento per l’energia degli Stati Uniti (DOE), lavora da anni ad un ampio portfolio di attività sull’idrogeno e le tecnologie correlate. Ad oggi, le Celle a Combustibile e le Tecnologie della filiera Idrogeno stanno diventando sempre più mature per diverse applicazioni; tuttavia per una diffusione a più larga scala restano da superare barriere quali i costi, la carenza di infrastrutture e la limitata produzione. Per rispondere a queste sfide, l’Hydrogen and Fuel Cell Technologies Office (HFTO) del DOE sta portando avanti un insieme articolato di attività di R&D e di dimostrazione di tecnologie abilitanti. Inoltre amministra 17 laboratori negli USA con eccellenze riconosciute a livello internazionale, oltre 50 Nobel ed esperti impegnati ad affrontare le maggiori sfide energetiche del nostro tempo.

Sunita Satyapal

Director, Hydrogen and Fuel Cell Technologies Office, U.S. Department of Energy

Hydrogen is receiving increased attention worldwide for its role as a zero-carbon energy carrier that can impact hard-to-decarbonize sectors, as well as provide long duration energy storage for intermittent renewables like solar and wind. At the U.S. Department of Energy (DOE), hydrogen and related technologies have been part of a comprehensive portfolio of activities for many years to enable emission reductions as well as resiliency, economic growth, and energy security. While fuel cells and hydrogen systems are becoming more available for multiple applications like stationary power, transportation and industrial use, the primary barriers to widescale availability across sectors are still: cost, infrastructure and limited scale.

To address these challenges, DOE’s Hydrogen and Fuel Cell Technologies Office (HFTO) has a comprehensive portfolio of activities in research and development (R&D) as well as enabling demonstration and deployment. DOE also has stewardship of seventeen national laboratories across the U.S. with world-class, unique capabilities and over 50 Nobel Prize winners and experts tackling some of the most pressing energy challenges of our time.

Market-driven targets to help the research community

HFTO has launched consortia with national lab core capabilities to address hydrogen production, storage, and fuel cells, and is funding industry and universities to join in these consortia to enable technology advances and address key targets.

These market-driven targets help guide the research community and are based on what is necessary to achieve parity with conventional commercial technologies or emerging advanced technologies in terms of cost, performance and other consumer expectations. For example, for transportation applications, the cost of hydrogen production must be less than $2 per kilogram (kg) and the cost of delivery and dispensing to the vehicle must also be less than $2 per kg, to be competitive with today’s internal combustion vehicles. For large scale industrial and power generation applications, the cost of hydrogen must be less than $1 per kg due to the low cost of shale gas in the United States. However, today the cost of hydrogen production from electrolysis is about $5 to $6 per kg and cost must still be reduced.

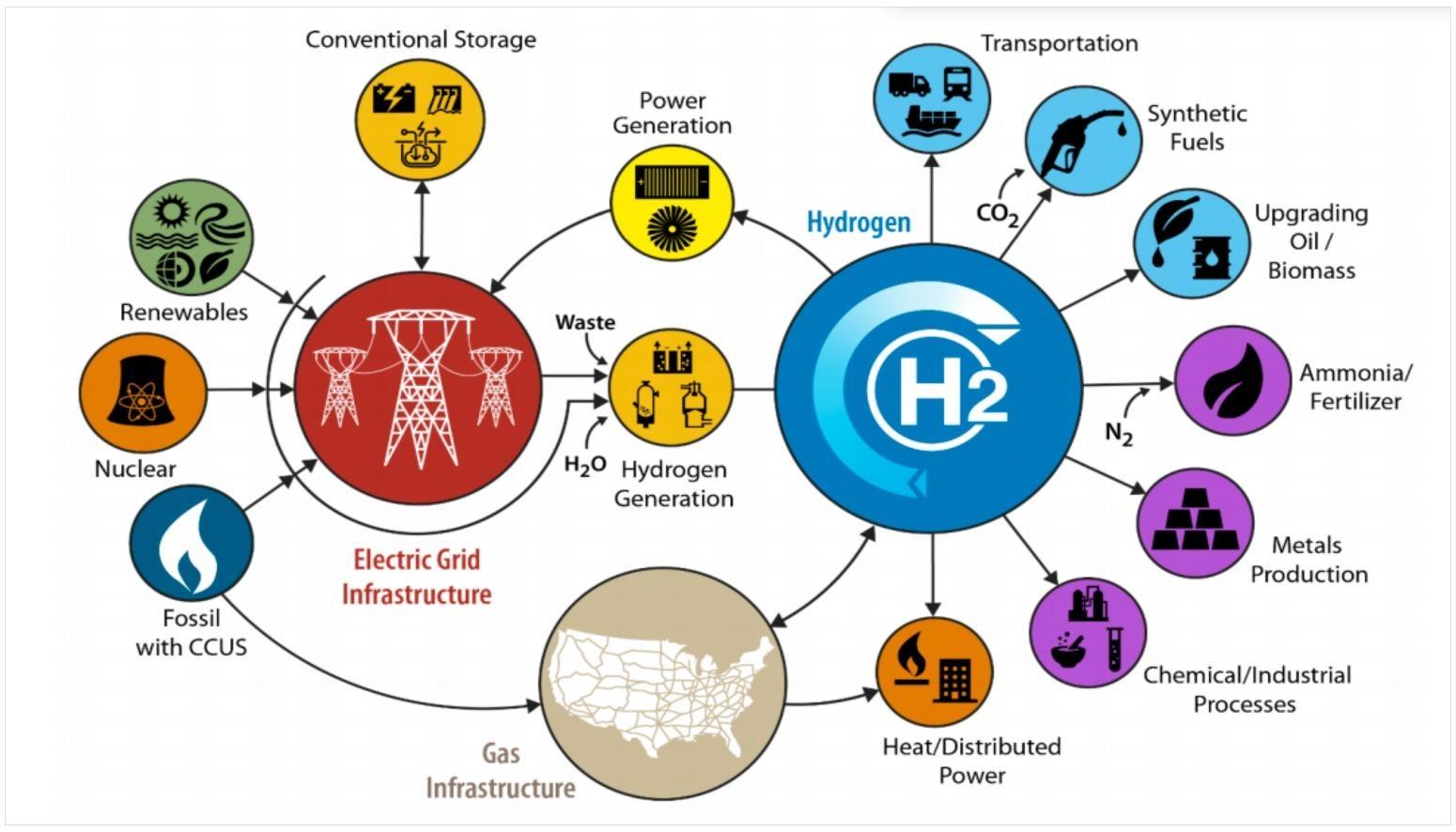

In addition to R&D, to enable economies of scale, DOE’s HFTO launched the H2@Scale initiative (see Figure 1) to enable large scale production, storage and end use of hydrogen, catalyzing the development of infrastructure and further reduction in cost. Producing hydrogen through electrolysis can enable greater penetration of intermittent renewables like wind and solar, as well as operation of baseload power plants, such as nuclear power. Hydrogen can also be produced from other diverse domestic resources in sustainable and carbon-free ways, including from fossil fuels with carbon sequestration.

The U.S. already produces 10 million metric tons of hydrogen, about one seventh of the global supply, and recent analyses shows the potential for a 2 to 4 fold increase in the economically viable production of hydrogen. End uses can include diverse areas such as the production of ammonia, chemicals and biofuels, as well as steel manufacturing, petroleum refining, transportation, and the power sector. By increasing the supply of hydrogen and co-locating end use at scale, we can pave the way for lower cost hydrogen infrastructure.

Infrastructure in the U.S. includes three large-scale geological caverns to store hydrogen, including the world’s largest hydrogen storage cavern in Texas, over 1,600 miles of dedicated hydrogen pipelines, and nearly a dozen large scale liquefaction plants, including those soon to be constructed. In terms of hydrogen fueling stations, approximately 45 commercial retail stations are currently open, mostly in California with plans for up to 200 by 2025 to meet the projected growth in fuel cell vehicles.

One of the areas of growing interest is heavy duty fuel cell trucks and plans are underway by several industry players to develop such trucks for the transport of goods over long driving ranges. This will also enable a corridor of stations and infrastructure to be available for emerging truck fleets and help drive down cost. And this also complements the strategies for large scale electric vehicle charging infrastructure for battery vehicles.

Fuel cell forklifts and the importance of hydrogen safety

Perhaps the most noteworthy example of how DOE helped to catalyze an emerging niche industry in hydrogen was the case of fuel cell forklifts. By cost-sharing the demonstration of early forklifts a decade ago, the U.S. now has roughly 40,000 hydrogen fuel cell forklifts in warehouses at major companies and over 100 fueling stations just for this industry. Working with the developing industry has been critical.

The DOE program also emphasizes the importance of hydrogen safety, codes and standards. For instance, the program developed H2Tools.org to disseminate information and supports the Center for Hydrogen Safety (www.aiche.org/chs) which has numerous partners from industry and governments in different countries, to develop training materials and other safety resources. Such efforts are made available for global players to join, and to share information on lessons learned and best practices to accelerate global progress towards a carbon-free economy. While hydrogen is just one part of a broad portfolio needed to meet our climate goals, continuing to accelerate progress and impact the hard to decarbonize sectors will be essential to meet the challenging timelines ahead of us.