Energy consumption analysis and carbon footprint of a building of the University of Milano-Bicocca: starting point for a sustainability report

This study was carried out in order to provide scientific data allowing to take decisions for a correct energy management of a building, with the aim of reducing waste and energy consumption and improve environmental (lower emissions) and economic performance of the buildings of the University

Analisi del consumo di energia e impronta carbonica di un edificio dell’Università di Milano-Bicocca: punto di partenza per un rapporto sulla sostenibilità

Questo studio è stato realizzato per fornire dati scientifici che consentano di prendere decisioni per una corretta gestione energetica di un edificio universitario, con l’obiettivo di ridurre rifiuti e consumo di energia e migliorare le performance ambientali (minori emissioni) ed economiche degli edifici dell’Università

DOI: 10.12910/EAI2013-10

G. Magatti, C.Bellantoni, M. Cavallotti, R. Benocci, M. Gualtieri, M. Camatini

Introduction

Climate change is one of the major challenges facing both population and the environment. Greenhouse gas (GHG) emissions, released into the atmosphere in ever rapidly growing volumes, are responsible for this change. The European Union defined the actions and the procedure that the EU member States must adopt to reduce the GHG emissions and counteract climate changes. The Directive 2009/29/EC, called “climate, energy, environment 20-20-20” aims to a 20% emission reduction by 2020, with 20% of energy produced from renewable sources.

The Carbon footprint (CF) is defined by JRC (2007) as the overall amount of carbon dioxide (CO2) and other GHG emissions (e.g., methane, laughing gas, etc.) associated with a product (goods or services) along its supply-chain. CF is therefore a useful indicator to calculate the emission baseline for a system, to determine the priority for impact reduction and to monitor the improvement achieved by applying different procedures.

Although the importance of CF is recognized, no standardized procedure for its calculation is available, even the norm UNI EN ISO 14067, describing the procedure for products CF, is about to be published (ISO/CD 2012).

At present CF calculation refers to the Life Cycle Assessment (LCA) methodology regulated by ISO 14040-44 and it can be seen as an LCA analysis where results are expressed only in terms of “Global Warming Potential in 100 years” (GWP100) impact category, measured as equivalent amount of CO2 (eqCO2) emitted (Pernigotti, 2011).

ISO 14064 (GHG management and related activities, CEN 2006) and the British standard PAS 2050 (CF calculation for goods and services, British Standard Institution, 2011) are so far the only reference standard guidelines directly dealing with CF measurement.

Public Administrations (PA) are required to reduce their consumption of energy and Universities have to contribute with specific plans or actions. The University of Milano-Bicocca has thus decided to start the evaluation of the CF of its buildings, after the stipulation of a voluntary agreement with the Ministry of the Environment, Land and Sea, which promotes projects aimed at analysing, reducing and neutralizing the impact of the University services on climate. Under this agreement, the University will adopt a methodology for calculating the CF on the consumption of electricity and thermal energy in their buildings. The project “Carbon Footprint of the University of Milan Bicocca” intends to evaluate the energy consumption in buildings, which plays an important role in CF calculation, particularly in the allocation of emissions of eqCO2 (GWP impacts in LCA-analysis) since electricity is produced mainly by fossil fuels.

This is therefore the first analysis carried on within the University with the assessment of the energy consumption and related CF of the building U7, with a surface area of 27,891 m2. This analysis intends to create a model of investigation, applicable to the other University buildings.

The U7 thermal energy comes entirely from the network of district heating and cooling and therefore its impact on the building CF has not been taken into account.

A survey was conducted during the evaluation, in order to identify the categories of electricity used in the building. These data have been used to assign the eqCO2 emission to the identified categories and to propose energy saving strategies, so as to reduce the CF and the relative environmental impact.

Description of the U7 building

U7 was built in 1994 by renovating and expanding a previous existing building. It is divided into two large courtyards and the structure is made of reinforced concrete and masonry parts. Three faculties are housed in the building: Economics, Statistics and Sociology: five departments belong to U7, where a bar and a cafeteria are located. 500 people are permanently employed. The building has four floors and a basement, and occupies 27,891.22 m2. Under the building there is a parking lot of 11,369.48 m2. The building rooms are mainly used as offices and classrooms, whereas there are few computer labs and no technical labs.

The building is also provided with an underground parking lot of a total surface of 11370 m2.

The building has a horizontal surface of 4,910.32 m2 net of windows and any other punch. The casing is mainly made up of masonry concrete blocks of various thicknesses, covered by insulation (XPS extruded polystyrene skinless, 4-6 cm). The S/V ratio is 0.26 m-1. According to the energy rating, U7 is placed in class D (for non-residential buildings, with 27 ≤ EPh <43 kWh/m3y)[1]. In the following Tables (1 and 2) some identity data for the building are reported.

TABLE 1

|

Identity data |

Edification year 1994 |

|

Address |

Via Padre G. Beccaro |

|

Destination of use (D.P.R. 412/1993) |

E.7 Buildings used for school activities at all levels and similar |

|

Usable area (m2) |

20318.88 |

|

Building volume (m3) |

109328.4 |

|

ENERGY DATA |

|

|

Results conform to the calculation procedure n.15833 - 13/12/2007 |

kWh/(m3 year) |

|

Specific requirements of primary energy (heating) EPH |

40.6 |

|

Specific energy requirement of the housing ETH |

38.7 |

|

Contribution of specific energy from renewable sources - EFER |

0 |

|

Winter heating |

District Heating |

|

Summer conditioning |

District Cooling + 5 refrigerator groups |

Identity data of Building U7

TABLE 2

|

Floor |

Surface (m2) |

|

1 |

5,143.99 |

|

2 |

3,938.60 |

|

3 |

3,941.06 |

|

4 |

3,847.52 |

|

0 |

5,227.02 |

|

-1 |

5,793.03 |

|

Tot Surface |

27,891.22 |

Building U7 floor surfaces

Electric energy consumption evaluation

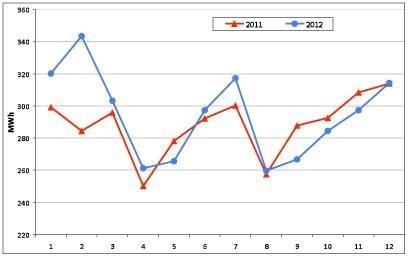

The data, obtained from the technical university office (named RIS), were related to the average monthly electricity consumption of the building during the years 2011-2012 (Figure 1). The average consumption of electricity in the selected period was above 291.3 MWh/month.

The electricity consumption for the years 2011 and 2012 (Figure 1) shows that the lowest contributions are in April (250.2 MWh) and August 2011 (257.6 MWh) and 2012 (259.8 MWh): during these months heating and cooling were not used, due to specific weather condition in April, and to summer vacations in August. The highest cooling and heating values are in July and December.

A comparable trend over the two years can be defined, except for the two anomalous months of January and February 2012. The difference between January 2011 and 2012 is related to the different closing days (winter holidays, New Year's Day and Epiphany) which were more in 2011 compared to 2012.

Since the use of the structure is the same in the two years (number and hours of lessons almost equal, so unchanged in the presence of students as well as for employees), the difference is due to the weather conditions and to the anomalous operation of electrical equipment (for conditioning) as explained below.

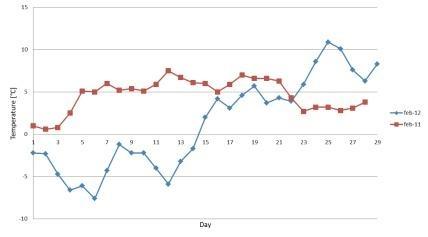

The high value of February 2012 is apparently due to the external temperature, about 3 degrees lower than in February 2011 (Figure 2). Moreover February 2012 had an extra working day with respect to 2011, for a leap year)[2].

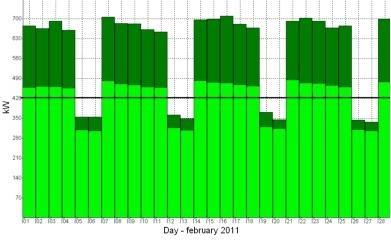

To explain the anomalous data of February 2011 and 2012 we compared the relative daily electricity consumption trends. The average daily consumption (Figures 3 and 4) is higher in 2012 (495 kWh/day) than in 2011 (424 kWh/day). Surprisingly the value of consumption in the first two weekends of February 2012 (Figure 4) is very high compared to the mean weekend value of February 2011. This consumption was related to a continuous heating during the weekends, for the low temperatures of that period (Figure 2).

Identification of electrical equipment/electronic devices and energy consumption evaluation

A detailed survey (inspection and inventory analysis) was performed in order to collect data of all the electrical and electronic equipment in the building, to determine their energy consumption and to relate this information to the monthly and annual energy measures.

The survey has recorded all the sources of power consumption (lighting, elevators, computers, wi-fi equipment, vending machines, SIFA terminals, fan coils) in the building areas (classrooms, common areas, laboratories).

Wherever possible, in terms of free access to the offices and inspection of the equipment, every kind of device was counted precisely. For classrooms, laboratories and offices a random sampling was carried out to characterize the average equipment composition of each room type. The data collected were sorted and classified by subdividing the spaces taking into account a similar typology and homogeneous size. The consumption and usage times of the single components were obtained from RIS office registry. For the definition of timetables of classroom use (600 h/year) and of computer labs, the scheduled times, indicated in the teaching plan for the academic year 2011-2012, were considered.

The annual energy consumption obtained from the survey data and the RIS office registry are reported in Table 3.

TABLE 3

|

Calcolated consumption |

Measured consumption |

|

3160.453 MWh/year |

3495.66 MWh/year |

|

Difference |

9.59% |

Difference in the consumption of calculated and measured energy

This difference (9.59%) may partly depend on errors in the allocation of operating hours of the devices: for example, some devices are left powered on permanently (e.g., computers); another possibility is related to a lack of control in the illumination management of classrooms and offices.

However, the 10% difference resulted to be small enough to proceed with the consumption allocation to different typologies of devices and/or area of use. Thus the identification of points of energy wastage and the opportunities of intervention were considered possible.

Calculated consumptions were allocated to determine specific values for different use categories and they were aggregated according to the use of the analysed spaces (Table 4).

TABLE 4

|

Classrooms |

Office |

Computer labs |

Common areas |

Infrastructures |

Canteen-bar |

Tot |

|

|

Chillers |

114474.6 |

173619.81 |

122279.1 |

38158.2 |

30526.56 |

5723.73 |

484782 |

|

Fancoil |

101568 |

105685 |

|||||

|

Extractors |

9462.86 |

7412.57 |

1577.14 |

3154.29 |

473.14 |

22080 |

|

|

Electric pumps |

217644 |

170487.8 |

36274 |

72548 |

10882.2 |

507836 |

|

|

MV |

74501.49 |

58359.5 |

12416.91 |

24833.8 |

3725.07 |

173836.8 |

|

|

UPS |

48205.03 |

37760.6 |

8034.17 |

16068.3 |

2410.25 |

112478.4 |

|

|

E.P. uplift |

3548.57 |

2779.71 |

591.43 |

1182.86 |

17.43 |

8280 |

|

|

UTA |

304354.29 |

238410.86 |

50725.71 |

101451 |

15217.71 |

710160 |

|

|

Condit. Autonom. |

110400 |

110400 |

|||||

|

Computer labs |

120693 |

120693 |

|||||

|

Classrooms |

53805 |

53805 |

|||||

|

Offices |

243299.52 |

243299.52 |

|||||

|

WiFi |

2803.2 |

2803.2 |

|||||

|

Sifa |

6570 |

6570 |

|||||

|

Distributors |

18921.6 |

18921.6 |

|||||

|

WC |

7451.6 |

7451.6 |

|||||

|

Server rooms |

26280 |

26280 |

|||||

|

Data centers |

26280 |

26280 |

|||||

|

Lighting |

90739.6 |

90739.6 |

|||||

|

Emergency lamps |

7919.04 |

7919.04 |

|||||

|

Elevators |

176327.4 |

176327.4 |

|||||

|

Canteen-bar |

147942 |

147942 |

|||||

|

TOT kWh/year |

825995.83 |

1033698.4 |

352591.47 |

348137 |

413479.4 |

186551.5 |

3160453.16 |

|

% |

26.14 |

32.71 |

11.16 |

11.01 |

13.08 |

5.9 |

100 |

Allocation of annual consumptions (years 2011-2012; kWh/year)

Among the various equipment examined, the electric pumps, chillers and AHU (air handling unit) resulted to be responsible for the highest amount of consumption.

Furthermore offices and classrooms were the major sink of energy with a consumption of 33% and 26%, respectively.

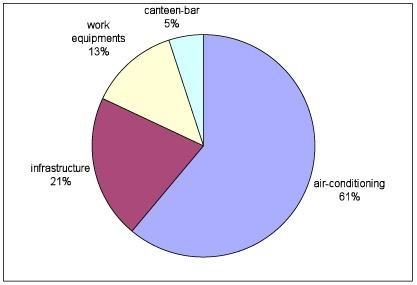

All the equipment and the relative consumption were then grouped according to the four categories of use: infrastructure, air conditioning, work equipment (in use in office, laboratory and classrooms), and canteen-bar.

The resulting data evidence that the consumption related to the air conditioning system (heating, cooling and ventilation) represents 61% (with 1,936,826 kWh/year), infrastructures 20.8%, Labs-class-offices 13.2%, Canteen-bar 4.68% for a total amount of 3,160,453 kWh/year (Figure 5).

Carbon footprint calculation

Building U7 eqCO2 calculation was made using Gabi5 software, according to ISO 14040-44 (2006) standards; calculation methodology used was CML2001 - Nov. 2010, and selected impact category was Global Warming Potential (GWP 100 years).

EqCO2 marker was used since all GHG values are related with specific conversion factors that have been chosen according to IPCC indications.

Electricity

The building CF, for electricity consumptions, amounts to 1758.68 t eqCO2. This value has been calculated considering the average consumption of 3495.656 MWh/year, calculated by using the data of 2011 and 2012. As for the electric power, acquired from A2A power supplier, specific emission factors were considered since the power grid mix used by A2A ensures to Bicocca University a lower emission factor in comparison with the national one[3]. In fact A2A supplies more renewable electric power than average national suppliers, causing a saving of 0.048 kg eqCO2/kWh with respect to the reference Italian power grid mix. This saving amount resulted to be approximately 160 t eqCO2/years for the building U7.

Considering the building surface, eqCO2 emission divided per unit surface (square meter), is 63.055 kg eqCO2/m2. This value has been compared to literature values or has been calculated by Polaris Centre in order to understand the building efficiency.

TABLE 5

|

Building |

GHG emissions (kg eqCO2/m2) |

|

Bicocca’s building U7 |

63 |

|

Other university (literature) |

69 |

|

Epson Italy Company (Polaris) |

60 |

|

Assimpredil-ANCE (Polaris) |

88 |

Equivalent CO2 emission/m2 measured in different buildings (kg eqCO2/m2)

Thermal energy

The University of Milano-Bicocca buys district heating and cooling from the network and this operation saves a share of CO2 emissions.

To better compare building U7 emission value with that of other buildings, the hypothetical emissions, produced by the use of heating and cooling traditional equipment by the University (gas boilers and air conditioners powered by electricity) have been evaluated. Thermal energy consumption is reported to be 2370 MWh in 2011 and 2452 MWh in 2012, with an average of 2411 MWh/year. This mean value was used for the calculation of the potential impact of traditional equipment.

Energy produced by a natural gas boiler, used for heating during the winter period (Jan., Feb., Mar., Nov., Dec.), and electricity consumption for air conditioners during summer were taken into account (Table 6).

TABLE 6

|

MWh |

MJ |

|

|

Winter |

1708.5 |

6150550.79 |

|

Summer |

702.5 |

2528979.77 |

|

TOTAL |

2411 |

8679530.56 |

Thermal energy in winter and summer (MWh and MJ)

These amounts of energy consumption would be responsible for the emission of 641.628 t eqCO2. This calculation has been performed with GaBi software (Calculation Method: CML2001 - Nov. 2010; Impact Category: GWP 100 years); the result demonstrates a reduction in the GHG emission of above 25%.

Total consumptions

The analysis has been extended to the parking of the building, placed at -1 level. The energy consumption of this area resulted to be 236,269.25 kWh/year, corresponding to 118.843 t of eqCO2.

If all the parameters are considered, the total emission (2519.15 t eqCO2) is the sum of the following contributions:

Electricity = 1758.68 t eqCO2

Thermal energy = 641.63 t eqCO2

Parking = 118.84 t eqCO2

referred to an area of 39,260.7 m2.

The ratio “total emissions/surface” gives 64.16 kg eqCO2/m2.

These calculations are complete since they consider all the emissions of U7. However only the emissions related to energy consumption (excluding parking and thermal energy) will be considered for the comparison with the other buildings to be monitored.

Conclusions

This study was carried out in order to provide scientific data allowing to take decisions for a correct energy management of the building, with the aim of reducing waste and energy consumption and improve environmental (lower emissions) and economic performance of the buildings of the University.

Since lighting and heating of the offices are fully dependent on individual users, the possibility for each user to manage his/her own settings consciously is a critical step for the proper use of the energy resource. Raising awareness of correct behaviour could lead to the reduction of consumption and waste.

For this reason, in parallel with the data analysis, a questionnaire was delivered to the permanent workers operating in the building, in order to understand their habits of energy consumption for lighting and for the use of electrical and electronic equipment.

The preliminary results of the questionnaire and the analysis of energy consumption have shown that an effective reduction of wastage can be achieved through measures on the management of air conditioning and lighting of common areas (hours of operation, improved efficiency, proper maintenance), and by raising awareness in the users to behave more sustainably.

Therefore energy efficiency of the building may be initially improved without structural interventions on the building itself (windows replacement, casing…), which will require high financial allocation. The containment of wastage and consumption, properly calculated, is thus a key step for a more sustainable energy managing of public buildings.

Moreover, assuming a cost per kWh equal to 0.18 € (derived from the contract for the supply of electricity for the University - RIS data), a reduction of U7 energy consumption of approximately 10-12% per annum –which can be reached by different behaviours and improved energy management– would allow annual savings of about 60,000-75,000 €/year. These resources could be invested in energy improvements of the structure, or released to fund university research, with undoubted benefit.

Finally, with a view to continuous improvement, the resources saved (acting on consumption, wastage and user behaviours) in structural interventions could lead to further increase the energy efficiency of the building over time, a process required by all industry regulations starting from ISO 14001.

In conclusion, the present study showed that simple precautions related to management and different energy behaviours of workers, without structural measures, may save energy by 10-12%, and the associated emissions of CO2. Obviously, these actions would also have a significant economic return, considering the total cost of electricity for U7 of about 600,000 € per year.

The primary actions to be undertaken are thus related to the electrical and electronic equipment and lighting use, and both managers and users must be involved in this energy waste reduction plan. The incoming months will then be used to launch a public awareness information campaign for the University employees.

The air conditioning management system seems to be as well a large intervention sector, although the main actions for a good practice have to be undertaken by the building managers.

The results and the methodology here reported represent a pilot study, which is going to be used as a base model for the assessment of CF and energy consumption of the other Milano-Bicocca University buildings.

Acknowledgements

This research has been supported and financed by the General Administration of Milano-Bicocca University. Thanks are due to Dr. L. Legnani for collecting the data used in the research.

References

Airaksinen M., Matilainen P., 2011, A Carbon Footprint of an Office Building, Energies 2011, 4, 1197-1210

Baldo G., Rossi S. e Marino M., 2008, Analisi Del Ciclo Di Vita LCA, Edizioni Ambiente, Nuova Edizione Aggiornata, Milan.

BSI, British Standard Institution, 2011, PAS 2050 Specification for the assessment of the life cycle greenhouse gas emissions of goods and services.

CEN Comité Européen de Normalisation, Environmental management - Life cycle assessment – Principles and framework: UNI EN ISO 14040, 2006.

CEN Comité Européen de Normalisation, Environmental management - Life cycle assessment - Requirements and guidelines: UNI EN ISO 14044, 2006.

CEN Comité Européen de Normalisation, Environmental management – quantify, monitor, report and verify greenhouse gas emissions: UNI EN ISO 14064 (three parts), 2006.

United Nations Intergovernmental Panel on Climate Change – IPCC, 2007, Climate Change 2007, the Fourth Assessment Report.

Committee Draft ISO/CD 14067.2, 2012, Carbon footprint of products - Requirements and guidelines for quantification and communication.

EIA – Energy Information Administration, 2007, Voluntary reporting of greenhouse gases program, fuel and energy source codes and emission coefficients, Washington DC.

European Platform on Life Cycle Assessment, European Commission – Joint Research Centre Institute for Environment and Sustainability, 2007, “Carbon Footprint - what it is and how to measure it”, Bruxelles, Belgio, http://lct.jrc.ec.europa.eu/pdf-directory/Carbon-footprint.pdf.

Iraldo F., Melis M., 2012, Green Marketing, come evitare il greenwashing comunicando al mercato il valore della sostenibilità, in collaborazione con Assolombarda, Gruppo 24Ore.

Jones C., Kammen D., 2011, Quantifying Carbon Footprint Reduction Opportunities for U.S. Households and Communities, Environmental Science & Technology 2011, 45, 4088–4095

Pandey D., Agrawal M., Pandey J., 2011, Carbon footprint: current methods of estimation, Environ Monit Assess 2011 178:135–160.

Pernigotti D., 2011, Carbon Footprint - Calcolare e comunicare l'impatto dei prodotti sul clima, Edizioni Ambiente.

Rubik F., Scheer D., Iraldo F., 2008, “Eco-labelling and product development: potentials and experiences”, International Journal of Product Development, 6, 393:419.

Treedom srl, 2011, CO2 neutral Online Carbon Footprint Methodology, Version 1.0 (10 Agosto 2011), Firenze, Italy.

Università Cà Foscari Venezia, Direzione Generale – Ufficio Processi e Progetti Speciali (UPPS); Ministero dell’Ambiente e della Tutela del Territorio e del Mare, Direzione Generale per lo Sviluppo Sostenibile, il Clima e l’Energia. 2012 “Linee Guida per il Carbon Management degli Atenei. Case study: Università Cà Foscari Venezia”. Università Cà Foscari.

WBCSD – World Business Council for Sustainable Development, 2000, Measuring eco-efficiency: a guide to reporting company performance, Ginevra, Svizzera

WBCSD – World Business Council for Sustainable Development, WRI – World Resources Institute, 2004, The greenhouse gas protocol: a corporate accounting reporting standard, Ginevra, Svizzera.

G. Magatti, R. M. Gualtieri, M. Camatini - Polaris Research Centre - University of Milano-Bicocca

C. Bellantoni, M. Cavallotti, Benocci - University of Milano-Bicocca

R. M. Gualtieri - ENEA, Technical Unit for Technologies Development - Saluggia Research Centre

[1] EPh is the energy performance value of building heating. It represents the primary energy consumed to heat a square meter in a year. CENED website (Certificazione ENergetica degli Edifici, Energy Certification for building), body accredited at Lombardy Region.

[2] ARPA Lombardia, average daily temperatures in February 2011 and February 2012 (Milan, Viale Marche).

[3] A2A Electricity mix emissions value = 0,503 kg eqCO2/KWh; Italian Electricity mix emission value = 0,551 kg eqCO2/KWh.