The importance of operational flexibility in gas turbine power plants

Eugenio Giacomazzi - ENEA, Technical Unit for Advanced Technologies for Energy and Industry

DOI: 10.12910/EAI2013-35

Flexible and efficient gas turbines have a key role as back-up power plants in the near future power generation scenario to promote the diffusion of renewable sources of energy and make the idea of a low carbon world a reality.

Industrial combustion is still related to the majority of energy consumption in the world today, furthermore it is expected to continue to play a major role in the future, due to the increasing global demand for electrical energy production. The cost-effective production and use of energy with reduced emissions is a key aim in Europe. This may be achieved by increasing the efficiency of fossil-fuel-based energy conversion processes and by increasing the utilization of renewable energy sources. Gas Turbines (GTs) play a central role in power generation, due to their relatively low installed capital cost, their high flexibility, and their low emissions with respect to other energy conversion systems. Furthermore, renewable power plants, especially wind turbines (since wind day-ahead predictions are less reliable than solar ones), need to be backed up by fast-reacting gas turbine power plants to avoid outages in case of sudden and unpredictable source drops causing power fluctuations. Hence, as important parts of economic growth and increased quality of life, it is of utmost importance that gas turbines perform at maximum capacity and with minimum disruptions at all times.

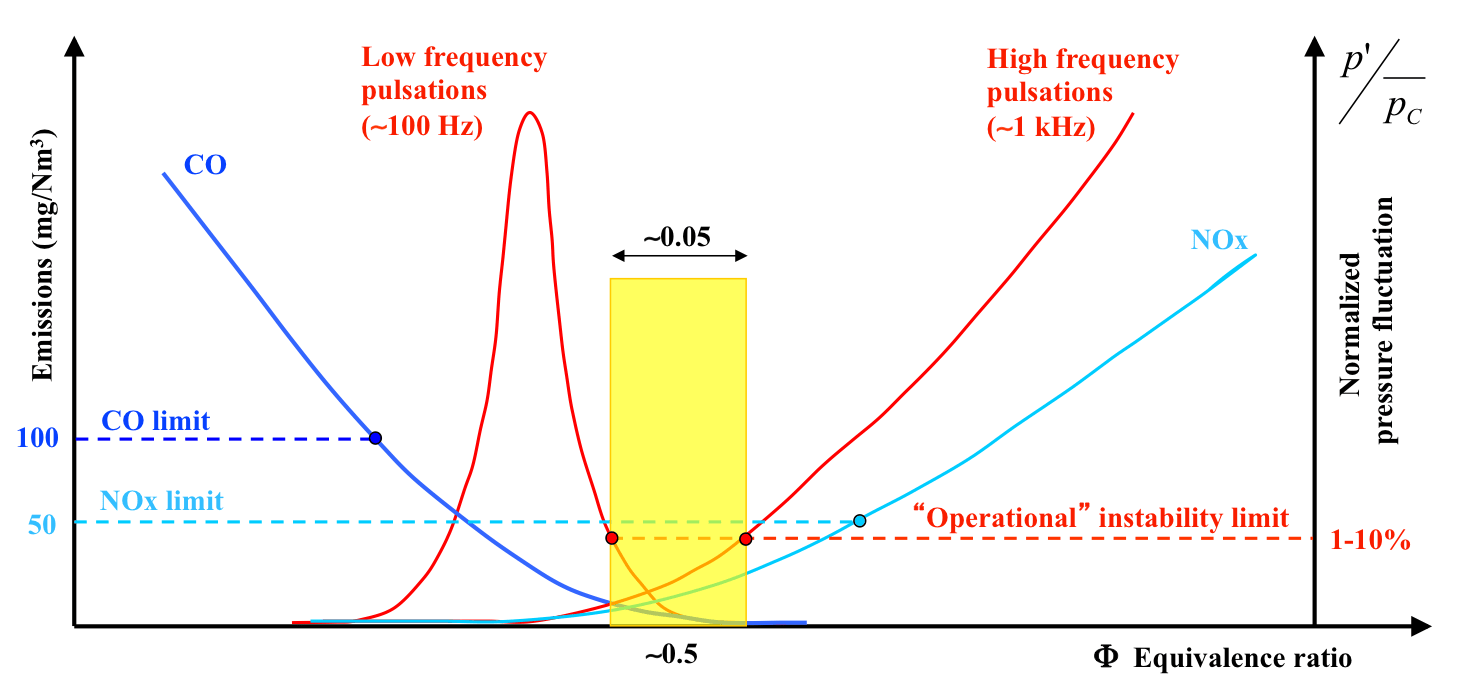

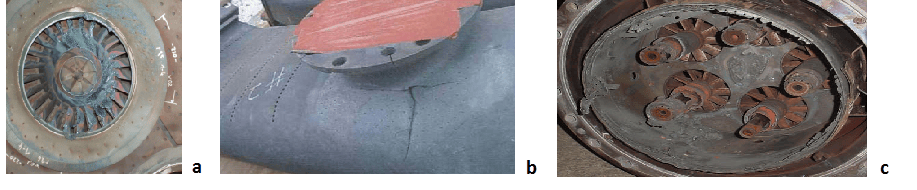

Lean Pre-Mixed (LPM) combustion is the state-of-the-art technology in stationary gas turbines for highly efficient low NOx emission power generation using natural gas. The counterpart for liquid fuels is the Lean Pre-mixed Pre-vaporized (LPP) strategy. By means of such technologies it is possible to operate gas turbines with pollutant emissions below the limits imposed by the European Industrial Emission Directives (see Figure 1). However, especially when operated close to the lean blow out limit, these combustion strategies tend to experience large amplitude pressure oscillations due to the coupling of pressure waves, associated to the acoustics of the combustion system, and heat release fluctuations [1-3]. These pressure oscillations can have amplitudes greater than 10% of the mean chamber pressure, however acceptable levels are much lower. Depending on the mechanical design of the combustion chamber and the frequency of the oscillations, typical limits set by manufacturers can be more than an order of magnitude lower than this. These undesired oscillations reduce the stable operating range of gas turbines (see Figure 1): they often tend to increase when working with leaner mixtures, but there are also combustion systems exhibiting some characteristic frequencies that increase with richer mixtures. These phenomena are commonly known as thermo-acoustic or “operational” combustion instabilities, or, more generally, as combustion dynamics. They may result in practical problems during gas turbine operation [4], with detrimental impact on reliability and availability. These instabilities may, in fact, cause flashback (see Figure 2a) [5] and lean blow out [6, 7], they may drive vibrations in mechanical components and, more dangerously, lead to the system failure (see Figures 2b-c) [8, 9], due to cyclic mechanical and thermal loads to the walls and turbine blades, or to cracked pieces liberated into the hot gas path.

Why improving operational flexibility

Combustion dynamics is expected to become an even more important problem in the near future for the efficient use of gas turbines. Europe, with its Energy Roadmap 2050, aims to show how to reach its decarbonisation objectives and ensure continuity of energy supply, with clean, efficient and safe power generation. There are two main paths to reach these goals: the first consists in burning alternative fuels, the second in increasing the share of renewable sources of energy. In particular, the European Energy Roadmap 2050 proclaimed that renewables will “move centre stage” and achieve “at least 55% in gross final energy consumption in 2050”[10, 11].

FIGURE 1

This sketch shows NOx and CO emissions, and normalized pressure fluctuation, as a function of the equivalence ratio. The nominal equivalence ratio and its stable range shown here are purely qualitative, the values being taken from a very few literature data. The pollutant emission limits reported refer to the Industrial Emission Directives (IED), burning natural gas (Nov. 2010). It is observed that, under the IED, the limits may be lower than those here reported, depending on what is agreed in the relevant Best Available Technology (BAT) Reference Document (BREF). Also individual site permit levels may be lower

FIGURE 2

Examples of damage. (a) Burner damage caused by flashback due to high levels of higher hydrocarbons [8]. If proposals to store / transport energy by adding hydrogen to the natural gas transmission system are implemented, the potential for flashback is likely to increase on some burners. (b) Cracks due to low-frequency (150 Hz) thermo-acoustic instabilities. (c) Damage due to high-frequency (2350 Hz) thermo-acoustic instabilities, in this case due to inappropriate tuning of the machine [9]

The growing interest in burning alternative fuels (e.g., syngas, biomass, liquefied natural gas, shale gas, hydrogen “blends” in general) [12] is motivated by the depletion of conventional fossil fuel for energy conversion[6], by the more commonly accepted CCS (Carbon Capture and Sequestration) techniques as the most promising answers to the issue of limitations on carbon-dioxide emissions, and by the growing acceptance of the POWER2GAS concept (e.g., converting electricity into hydrogen via electrolysis, or into synthetic natural gas) as an ideal way to store excess electricity from renewables (especially during the night time). Also the use of HENG (Hydrogen-Enriched Natural Gas) appears to be an economically sustainable solution to reduce the carbon intensity of natural gas, considering its compatibility (up to 20% hydrogen content in volume) with the existing transmission and distribution infrastructure, and end-use equipment [13]. Furthermore, it is observed that, depending on the gasification process and which solid is gasified, substantial differences in the resulting syngas composition occur (the CO and H2 contents mainly determine combustion properties in terms of flame speed, flammability limits and ignition delay time). Besides this, the international trading of natural gas increases and it seems economically impossible to define a gas quality harmonization code for the feeding network [10, 14]. All these issues increase the variability of fuel composition at the inlet of gas turbine combustors, thus leading to the need for more fuel-flexible gas turbines [6, 15, 16].

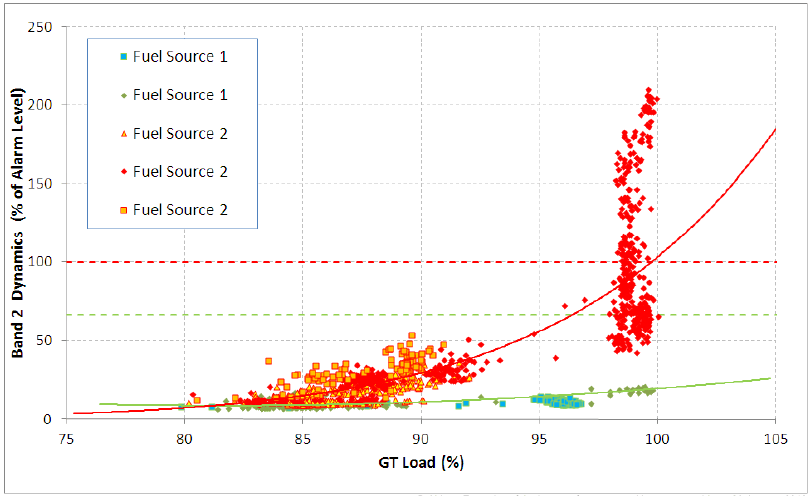

Practical examples of combustion dynamics issues associated with fuel composition variation have been reported [8]. Figure 3 shows an example of combustion dynamics exceeding alarm levels in a power plant (having two fuel sources) whilst using fuel from one source, even though both fuels were within the acceptable supply specification. This problem required restricted operation (via an immediate reduction in output) and was mitigated by retuning the machine on the second fuel source.

FIGURE 3

Example of combustion dynamics exceeding alarm levels due to fuel composition issues [9]

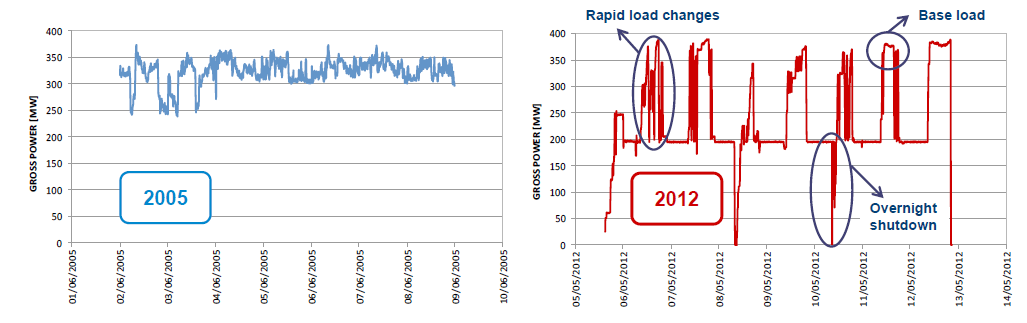

The increasing share of renewable sources of energy, unpredictably intermittent for their own nature, will produce power fluctuations in the electricity grid. Gas turbine plants not required to produce power have to be “parked” at the minimum environmental load or even shut down. In case of power fluctuations caused by renewable power plants, gas turbine power plants will be required to compensate for them [17]. Hence, they will be required to perform loading and unloading phases quicker than the current ones. National load ramps more than 5 GW/h are expected to be common. Simple GT cycles have typical ramping of 8% Full Load/min, a minimum load of 50% Full Load, and require less than 6 min for a hot start, i.e., to restart after a 12 (or less) hours off-line mode. Critical changes in managing some power plants are already experienced by users, as shown in Figure 4. These issues lead to the need for more load-flexible gas turbines.

Both the variability of fuel composition and the demand for quicker loading and unloading phases tend to enhance combustion dynamics whilst acceptable operation of gas turbines requires a “weak” dynamics. Upon this scenario, some main needs emerge: increasing fuel- and load-flexibility (both being operational flexibility) of present GT power plants, and consequently their efficiency, while maintaining safe operation conditions and low pollutant emission; identifying new more flexible GT cycles; integrating renewable and GT back-up power plants.

FIGURE 4

Typical weekly trend of a combined cycle power plant in Italy [courtesy of ENEL]. Power plant operation in 2012, with respect to 2005, shows an increased number of start-up / shutdown cycles, reduced operation at base load, and operation at minimum environmental load during night time

ENEA’s activities on gas turbine operational flexibility

The Sustainable Combustion and Processes Laboratory (COMSO) of the ENEA Technical Unit for Advanced Technologies for Energy and Industry (UTTEI), hosted in the Casaccia Research Centre (Rome), has been working on several issues related to operational flexibility of gas turbines since 2004.

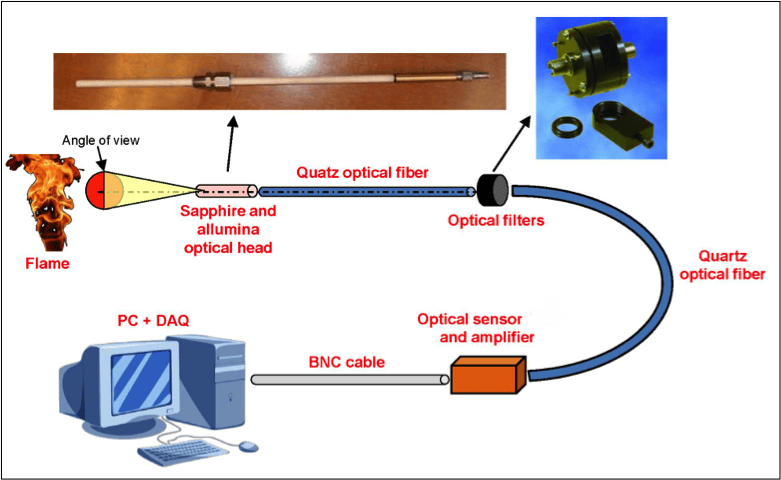

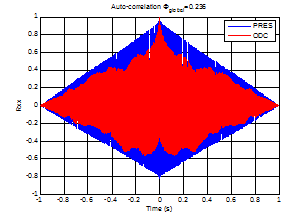

Most of its work aims at developing reliable and robust sensors able to operate in the harsh environment of gas turbine combustion chamber, and at developing signal analysis strategies for the early identification of instability precursors in real-time. In particular, ENEA patented the ODC (Optical Diagnostic of Combustion) system, the latest set-up of which is reported in Figure 5. This system consists of an optical sapphire head connected to a photo-diode by means of a quartz optical fibre. Optical filters may be used to focus on specific wavelengths (typically, OH radical line) or to remove unwanted bands (typically, the infrared emission of the combustor walls). The radiant energy signal of reacting regions is sampled at high frequency (from 200 kHz up to 1 MHz, depending on the application) and then analysed to identify characteristic pulsation frequencies during the operation of plants. Several tests [18, 19] were performed in many experimental facilities of ENEA (e.g., the COMET-HP plant) and of external operators (e.g., Savona Combustion Lab and ANSALDO rigs in Gioia del Colle), having different powers (from a few kW up to some MW) and burning different fuels (from natural gas, to hydrogen and oil). Measurements showed that the auto-correlation of the radiant energy and/or pressure signals might be a good index of combustion instabilities. An example of how the auto-correlation of such quantities looks like is reported in Figure 6. The proposed ODC technique, compared with pressure transducers, is more robust, standing higher temperature (2000 °C) than pressure sensors (900 °C), and has less intrusivity, due to its smaller size (1 mm optical fibre diameter). However, further work is required to establish what is the best technique between the ODC and pressure transducers (usually applied in power plants). It is likely that coupling information coming from both sensors will be the key to definitively identify combustion instabilities.

Recently, researchers in COMSO also worked on gas turbine “parking” strategies [19]. They modified the fuel injection in a V64.3A prototype burner of ANSALDO ENERGIA to extend its stable operation towards the lowest partial loads, using very lean mixtures, i.e., with 0.15-0.25 equivalence ratios. Tests were performed in the COMET-HP plant.

Besides these experimental activities, COMSO also investigates on the physical mechanisms of combustion instabilities by means of numerical simulation. Some researchers developed HeaRT (Heat Release and Turbulence), an accurate CFD (Computational Fluid Dynamics) code for Large Eddy Simulation (LES). LES is a technique allowing to capture the unsteady features of flows, hence particularly suitable to study operational instabilities and improve their understanding. Such a numerical technique requires high-performance computing, offered by the CRESCO platforms in the ENEA Portici Research Centre.

Some other researchers in COMSO also work on the development of advanced and more flexible gas turbine cycles. Recently, growing interest has been focused on cycles using supercritical CO2 as working fluid, for their high energy density, quick loading capability, and expected low-cost CO2 capture strategy.

All of the above activities are provided for in the Programme Agreement with MISE (the Italian Ministry of Economic Development). Recently, a big effort has been devoted to collaborate with other European research centres, academia and industries, with the aim of organizing common projects on gas turbine flexibility within the European Research and Innovation programme Horizon 2020. In particular, COMSO is active within the European Turbine Network (ETN), where it coordinates two Project Groups on “Dynamics, Monitoring and Control of Thermo-Acoustic Instabilities in Gas Turbines” and on “Supercritical CO2 Quickly-Ready Gas Turbine Cycles”. Together with other European partners, COMSO is also going to submit a Marie Curie ITN proposal on “Dynamics of Turbulent Flames in Gas Turbine Combustors Fired with Hydrogen-Enriched Natural Gas”.

FIGURE 5

Present ODC system set-up

FIGURE 6

Example of auto-correlation of pressure and radiant energy signals in unstable conditions

Conclusions

Operational flexibility is a key requirement for gas turbine power plants in the near future for a couple of reasons. Firstly, to the lack of a quality harmonization code for the gas injected in the distribution network: this increases fuel composition variability at the inlet of gas turbine combustors that have to operate stably (fuel-flexibility). Secondly, to the increasing share of renewable sources of energy in the electricity grid: this causes more likely power fluctuations to be compensated by means of gas turbine back-up power plants ready to work stably under loading and unloading phases quicker than the current ones, still maintaining low pollutant emissions (load-flexibility).

Upon this scenario, combustion dynamics and the risk of damage associated with combustion instabilities are expected to increase in modern lean premixed gas turbines. Although the detrimental effects of thermo-acoustic instabilities have been known for many years and significant research efforts have been dedicated to their understanding, monitoring and control, such problems are not fully resolved yet. Considering past and current literature on dynamics, monitoring and control of combustion instabilities, a lot of progress has been generally achieved in fundamental research, albeit with limited impact and exploitation in industrial applications. The effects of a varying H2-content in the fuel, the quality of premixing or a rapid change in load on combustion instabilities remain unclear. Also, the mechanisms leading to high-frequency oscillations are not well understood. In particular, industrial interest is focused on thermo-acoustic instabilities driven by transverse waves in annular combustors. Besides, sensor technology has made significant progress in recent years and is becoming available to monitor the combustion behaviour with innovative acoustical and optical systems. Investigating all these issues and integrating results will allow to develop more reliable control systems, operate gas turbines more safely with increased flexibility and availability, and guarantee the stability of the electricity grid.

Hence, “operational” combustion instabilities are not only an “intellectual challenge” in the combustion science domain, but also a crucial problem to be solved in view of future clean and efficient power generation. Hence, this fully justifies a synergic effort, cooperation and networking among researchers, users and producers of gas turbines to provide real-world-connected directions to fundamental research, improve the impact and exploitation in industrial applications, and put in practice the future clean and efficient power generation laid out in the European Energy Roadmap 2050.

Acknowledgements

The author gratefully acknowledges all the European Turbine Network members that expressed their interest in the “Combustion Instabilities” Project Group within ETN, especially David Abbott [E.ON] and Sergio Rizzo [ANSALDO ENERGIA], for their support through useful discussions, suggestions and sharing of information.

References

[1] Candel S.M. and Poinsot T.J., “Interactions between acoustics and combustion”, Proceedings of the Institute of Acoustics, 10:103-153, 1988.

[2] Culick F.E.C., “Combustion instabilities in liquid-fuelled propulsion systems-an overview”, Technical Report AGARD-CP-450, AGARD, 1988.

[3] Dowling A.P., “The calculation of thermoacoustic oscillations”, J. of Sound and Vibration, 180(4):557-581, 1995.

[4] Lieuwen T, Yang V, editors. “Combustion instabilities in gas turbine engines: operational experience, fundamental mechanisms, and modeling”, Progress in Astronautics and Aeronautics, 210:611–34, 2005.

[5] Tuncer O., Acharya S., and Uhm J.H., “Dynamics, NOx and flashback characteristics of confined premixed hydrogen-enriched methane flames”, Int. J. Hydr. En., 34:496-506, 2009.

[6] Lieuwen T., McDonell V., Petersen E., and Santavicca D., “Fuel flexibility influences on premixed combustor blowout, flashback, autoignition and stability”, ASME paper, GT2006-90770, 2006.

[7] Chao Y. C., Chang Y. L., Wu C. Y., and Cheng T. S., “An experimental investigation of the blowout process of a jet flame”, Twenty Eight Symp. (Int.) Comb., 2000.

[8] Abbott D., “Practical examples of the impact of variations in gas composition on gas turbine operation and performance”, Gas to Power Europe Forum, January 2012.

[9] Goy, C.J., James, S.R., Rea, S., “Monitoring combustion instabilities: E.ON UK’s experience”. Chapter 8 in [4], pp. 163-175, 2005.

[10] European Community Report, “Study on Interoperability, Gas Quality Harmonization, Cost Benefit Analysis, Preliminary report for consultation”, performed by GL Noble Denton and Pöyry Management Consulting, July 2011.

[11] European Community Report, “Energy Roadmap 2050”, COM(2011) 885/2, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, December 2011.

[12] Annual Energy Outlook 2012, early release overview, eia, U.S. Energy Information Administration, 2012.

[13] National Grid plc and Atlantic Hydrogen Inc., “Hydrogen-Enriched Natural Gas”, Report for Gas Industry Executives, Utility Regulators, Policy Makers and Energy Administrators, 2009.

[14] Bryant, N., Study on “Interoperability – gas quality harmonization – cost-benefit analysis”, GL Consultancy and Pöyry, contracted on behalf of the European Commission, to be released in January 2012.

[15] ETN, European Turbine Network Position Paper on “Gas Turbine Fuel Flexibility for Zero Emission Power Plants”, August 2007.

[16] ETN, European Turbine Network Position Paper on “Impact of Natural Gas Quality on Gas Turbine Performance”, Abbott D.J., Maunand J., Deneve M., Bastiaans R., February 2009.

[17] ETN, European Turbine Network Position Paper on “Enabling the Increasing Share of Renewable Energy in the Grid – Technological Challenges for Power Generation, Grid Stability and the Role of Gas Turbines”, May 2011.

[18] Bruschi R., Giacomazzi E., Giulietti E., Stringola C., Nobili M., Pagliaroli T., Giammartini S., “An optical technique for the identification and tracking of combustion instabilities”, Seventh Mediterranean Combustion Symposium, MCS-11, Cagliari (Italy), 11-15 Sept. 2011.

[19] Giacomazzi E., Giulietti E., Stringola C., Chiocchini S., Cassani S., Pagliari L., “Combustion Monitoring in Gas Turbines and Enhanced Stability at Very Lean Conditions”, GT2014-25506, Proceeding of ASME Turbo Expo, Dusseldorf, Germany, 16-20 June, 2014.